What we do

We specialize in the production and sale of drawn steel wires with diameters ranging from 1.20 mm to 12.00 mm.

We offer clean, bright, phosphated, hard, semi-hard, annealed, and straight-cut wires – all tailored to individual customer requirements.

Our products are used in the manufacturing of screws, bolts, meshes, nails, household appliance components, and many other metal products.

Thanks to modern production processes, our wires are suitable for mesh welding, 3D bending technology, electroplating, painting, and metalworking applications.

The wires are available in small rolls weighing from 50 to 300 kg or coils weighing from 450 to 1400 kg.

The diameter and dimensional tolerance can be adjusted according to the order specification.

We ensure high quality, strict control at every stage of production, and short lead times – as fast as five business days.

General information

We encourage you to read the detailed characteristics of each of our products using the tile menu. Below you will find general information that will help you better visualize what we do and what we offer. Haven’t found the answer to your questions? Please contact us – we will explain everything!

Grades of wire permanently available in our offer

The following steel grades are permanently available in our offer – which allows us to fulfill orders quickly. If you are interested in grades not included in our regular offer, please contact us via the contact form, e-mail or call us!

SAE 1008-U

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.06 – 0.10 | 0.30 – 0.50 | 0.15 – 0.25 | max. 0.04 | max. 0.05 | max. 0.07 | max. 0.10 |

SAE 1006-U

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.05 – 0.08 | 0.25 – 0.45 | 0.15 – 0.25 | max. 0.03 | max. 0.03 | max. 0.07 | max. 0.10 |

C4D1+B

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.03 – 0.05 | 0.20 – 0.35 | max. 0.05 | max. 0.025 | max. 0.025 | max. 0.07 | max. 0.05 |

C2D1

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| max. 0.03 | max. 0.20 | max. 0.03 | max. 0.02 | max. 0.02 | max. 0.06 | max. 0.03 |

C9D

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.08 – 0.10 | 0.40 – 0.60 | 0.15 – 0.30 | max. 0.03 | max. 0.03 | max. 0.07 | max. 0.10 |

C10C

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.08 – 0.12 | 0.30 – 0.50 | max. 0.10 | max. 0.025 | max.0.025 | – | – |

1018

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.15 – 0.20 | 0.60 – 0.90 | max. 0.10 | 0.04 | max. 0.05 | – | – |

S235JR

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| max. 0.17 | max. 1.40 | – | max. 0.035 | max. 0.035 | – | – |

20MnB4

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.18 – 0.23 | 0.90 – 1.20 | max. 0.30 | max. 0.025 | max. 0.025 | max. 0.30 | – |

23MnB4

| %C | %Mn | %Si | %P | %S | %Cr | %Ni |

| 0.20 – 0.25 | 0.90 – 1.20 | max. 0.30 | 0.025 | 0.025 | max. 0.30 | – |

Wire confection

We offer several methods of winding wire so that each customer can choose the option that best suits their needs. The most popular form of winding is a coil, but if you need a smaller quantity, we also offer small rolls or stands. Below you can find all available methods of winding wire, the dimensions of each type, and the diameters for which they are available.

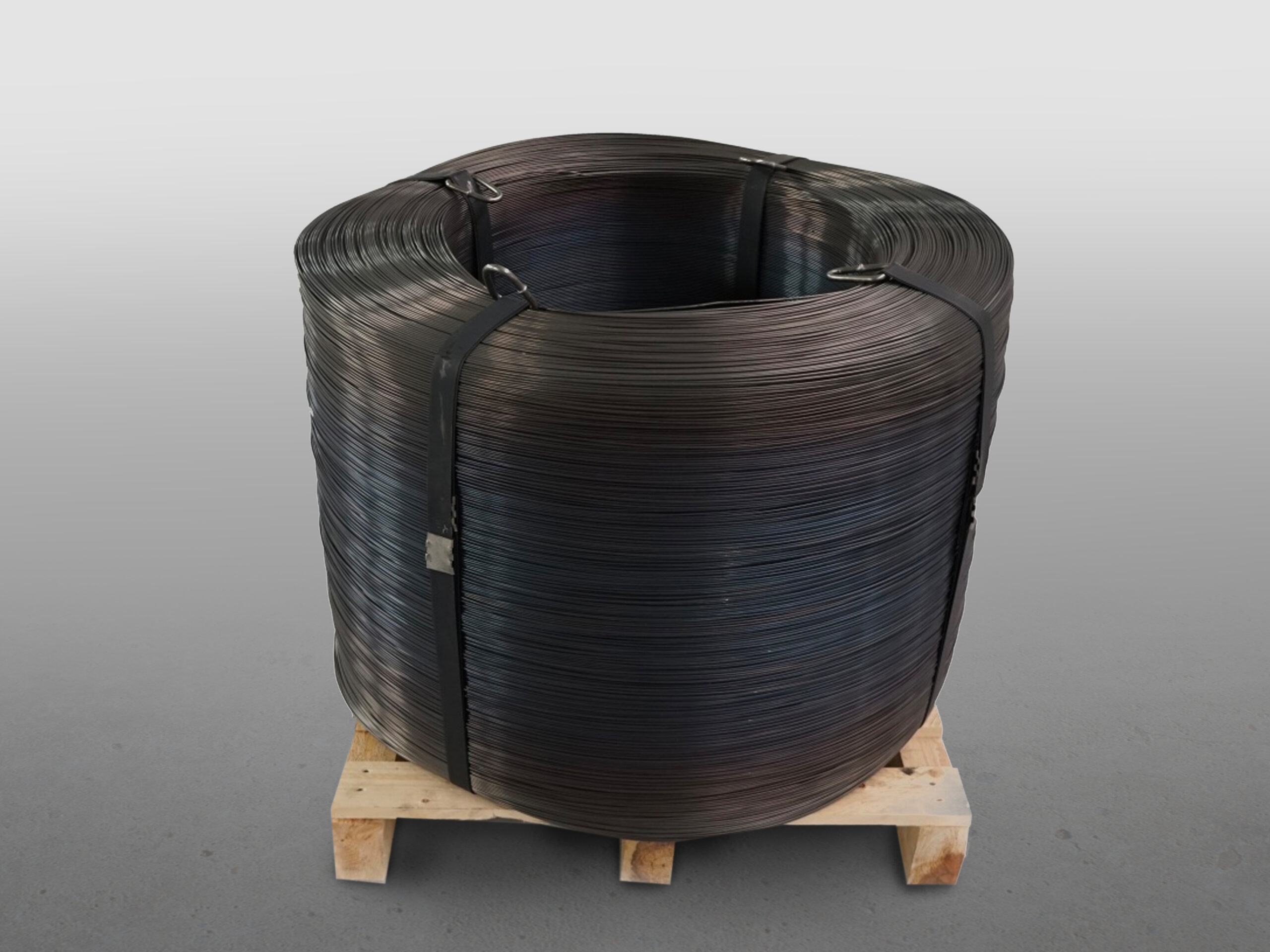

PRECISION LAYERING COIL

Dimensions

D1: 600 mm

D2: 700 – 900 mm

H: 600 mm

Available for diameters

5,50 – 12,00 mm

Weight

450 – 1400 kg

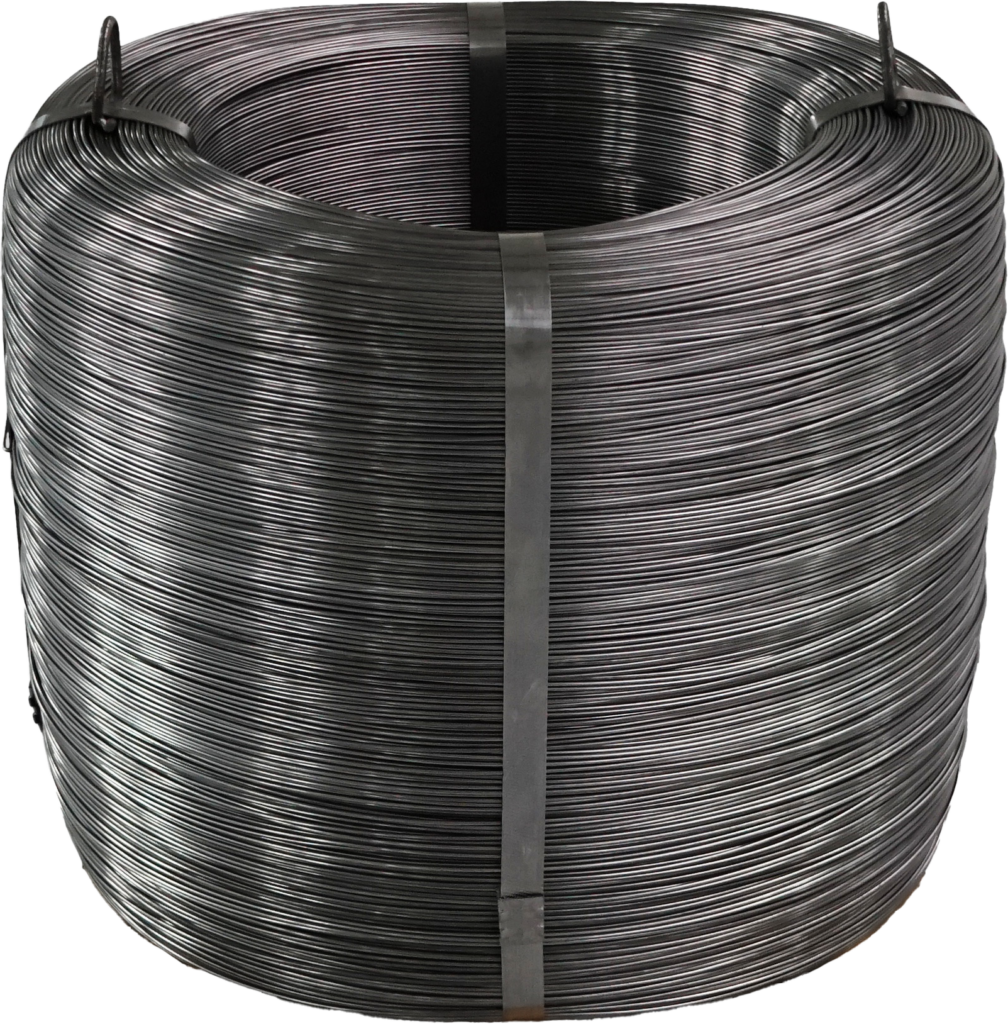

REGULAR COIL

Dimensions

D1: 500 mm

D2: 630 – 900 mm

H: 500 / 630 mm

Available for diameters

2,00 – 6,00 mm

Weight

450 – 1400 kg

STAND

Dimensions

D1: 550 mm

D2: 550 – 850 mm

H: 200 – 1400 mm

Available for diameters

2,50 – 6,00 mm

Weight

100 – 1200 kg

(depending on the wire diameter)

STAND

Dimensions

D1: 400 mm

D2: 650 mm

H: 200 – 1200 mm

Available for diameters

1,20 – 3,00 mm

Weight

100 – 600 kg

(depending on the wire diameter)

SMALL ROLL

Dimensions

D1: 450 – 550 mm

D2: 600 – 700 mm

H: 100 – 300 mm

Available for diameters

1,20 – 6,00 mm

Weight

50 – 300 kg

(depending on the wire diameter)